|

Hebei FengQi Machinery Co., Ltd.

|

orming and welding machine

| Price: | 15000.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

High-frequency pipe welding equipment

Carbon steel welded pipe forming and welding machine

Product Description

I. Summary

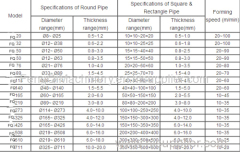

The mill is intended for manufacturing round pipe Φ32mm-Φ89mm with thickness of 1.5mm–4.5mm from cold-rolled and hot-rolled coil strip by means of unclosed tubular blank with its subsequent welding into tube, edge heating by means of solid state high-frequency welder, longitudinal seam welding in rolls of tube welding machine, cooling, further sizing or shaping and on-stream cutting of endless tube in measured lengths.

Finished product will be of round, square or rectangular pipe

II. The technical flow of the production line

{SteelTape}→→ Double-head un-coiler →→Strip-head Cutter and welder→→

Spiral Accumulator→→Forming section(Flattening unit +Main driving unit +Forming unit +Guide unit +High frequency induction welding unit +squeeze roller)+ De-burr frame →→Cooling unit →→ Sizing unit and straightener →→Flying saw under computer-control →→ Run-out table

2.Is to roll the steel strip of different sizes to the corresponding tube blanks of straight seam continuously through roll type forming, cage roll forming and FF/FFX forming ,then heated the tube edges to the welding temperature via high frequency induction or contact heating and completed the welding under the extrusion of the squeeze roller, after cooling ,sizing and strightening to be the requested straight seam steel pipe. Mainly composed by the forming section, the welding section, the sizing section, the transmission system and the electrical system etc.

FAQ

Professional Team

We are Manufactuer, have nearly Teneng have 15 design engineers and 20 commission engineer, all of them have more than15 years of experience in the tube mill industry.

Professional Training Service

•We shall provide the professional training service for the operation, maintenance and repairing.

•We also would send our engineers to our customers' factory for installation and testing.

•We shall provide the products absolutely fulfill your requirements and it would be a full turnkey service.

After Sale Service

We also would send our engineers to our customers' factory for installation and testing.

Reputable Products

we have exported our products to many countries and regions all over the world, especially Russia, Ukraine, Kazakhstan, Uzbekistan, ...